Just How Commercial Scales Job: A Thorough Overview for New Users

Understanding the mechanics behind industrial scales is essential for new users who wish to ensure accuracy in their dimensions. These tools count on lots cells and pressure scale innovation to convert weight into a quantifiable layout, yet the subtleties of their operation extend past plain capability. From the different types available to the essential techniques for correct use and maintenance, each facet plays a substantial duty in accomplishing reputable results. As we explore these components, one have to think about exactly how these elements engage to improve performance in varied industrial applications.

Fundamentals of Industrial Scales

Industrial ranges are necessary tools made use of across various fields, consisting of manufacturing, logistics, and farming, to guarantee accurate weight measurements of heavy loads. The fundamental principle behind commercial ranges includes the conversion of weight into a quantifiable kind that can be displayed electronically or analogically. These scales utilize numerous mechanisms, such as lots cells or mechanical levers, to figure out the weight of objects placed upon them.

In enhancement to their measurement capabilities, industrial ranges are made to hold up against rough settings, including robust building that resists dust, dampness, and hefty effects. Calibration and maintenance are essential to make certain accuracy, as even small disparities can bring about considerable financial effects. By recognizing the fundamentals of industrial ranges, individuals can appreciate their importance in numerous industrial applications.

Sorts Of Industrial Scales

Numerous kinds of commercial ranges satisfy the varied requirements of various markets, each developed to take care of certain considering jobs with precision and integrity. Among one of the most typical kinds are floor ranges, which are suitable for evaluating hefty and large things. These scales typically include large platforms and can suit palletized products, making them essential in storehouses and shipping facilities.

Another type is bench ranges, which are often utilized for smaller sized things in manufacturing and retail setups. They give accurate measurements for items that call for accuracy, such as chemicals or components in production line (Industrial Scales). For mobile procedures, mobile scales provide adaptability and ease of transport, appropriate for fieldwork or temporary setups

Additionally, specialized scales like checkweighers are utilized in manufacturing lines to keep top quality control by making certain that items satisfy weight specs. Each type of industrial range plays a critical duty in boosting functional effectiveness and accuracy across numerous fields.

Just How Evaluating Mechanisms Job

Considering systems are vital components that make it possible for exact measurement of mass across various industrial scales. These devices use various concepts of physics and engineering to provide specific weight analyses, important for inventory monitoring, high quality control, and compliance with governing requirements.

One common kind of evaluating mechanism is the tons cell, which operates the concept of strain determines. When a tons is used, the tons cell deforms a little, producing an electric signal proportional to the weight. This signal is after that converted right into an understandable weight dimension by the scale's electronic devices.

Another extensively used device is the mechanical balance, which uses a system of levers and weights. Industrial Scales. This approach counts on the concept of equilibrium, where the weight of the things being measured is balanced versus known weights, permitting direct measurement

In addition, pneumatic and hydraulic ranges take advantage of liquid characteristics principles to determine weight. These systems use the pressure put in by a lots to establish weight, providing high accuracy for huge lots.

Proper Usage Methods

When making use of industrial scales, sticking to correct use techniques is essential for preserving and making sure exact measurements equipment stability. It is necessary to pick the ideal range for your specific application, as scales differ in capacity and precision.

Before weighing, guarantee that the scale is put on a steady, level surface devoid of vibrations or disturbances. This will help to minimize mistakes triggered by exterior aspects. Additionally, calibrate the range according to the supplier's requirements before utilize, making sure that it is working correctly.

When placing things blog here on the range, disperse the weight uniformly to stay clear of tipping or damaging the tools. Constantly permit the scale to support before videotaping the weight, as changes may take place throughout preliminary placement. For bulk products, use containers that are ideal for the range size to stop overloading.

Furthermore, avoid positioning cool or excessively hot things directly on the scale, as temperature level variations can impact accuracy. Maintain the weighing system clean and cost-free of particles to prevent contamination and make sure reputable outcomes. By complying with these strategies, individuals can take full advantage of the performance and durability of their industrial scales.

Upkeep and Calibration Tips

Guaranteeing the long life and accuracy of industrial ranges requires attentive maintenance and routine calibration. A preventive maintenance timetable is important; it needs to include regular inspections to determine damage, particularly on tons cells and various other sensitive elements. Consistently cleaning the range's surface area and ensuring the bordering area is complimentary from particles will certainly help preserve its stability and efficiency.

Calibration is just as important and must be executed at regular intervals or whenever the range experiences substantial changes in temperature, humidity, or physical displacement. Use qualified calibration weights that are deducible to nationwide standards for accuracy. File each calibration session thoroughly to track efficiency gradually and identify any patterns or repeating concerns.

Train all drivers on appropriate scale use and upkeep procedures to guarantee consistent efficiency and accuracy. By sticking to these upkeep and calibration ideas, individuals can enhance the integrity of their industrial scales, making certain ideal operation in any kind of setting.

Verdict

Understanding the mechanics behind Industrial Scales industrial scales is crucial for new users that desire to make certain precision in their dimensions.Industrial ranges are necessary devices used across different sectors, consisting of manufacturing, logistics, and farming, to make sure precise weight measurements of heavy loads. The basic concept behind commercial scales involves the conversion of weight right into a quantifiable Look At This type that can be presented digitally or analogically. By comprehending the basics of commercial ranges, individuals can appreciate their relevance in numerous industrial applications.

In conclusion, recognizing the procedure and maintenance of industrial ranges is vital for making sure accurate weight dimensions in numerous applications. (Industrial Scales)

Kel Mitchell Then & Now!

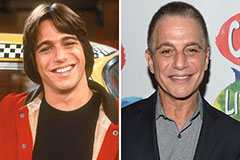

Kel Mitchell Then & Now! Tony Danza Then & Now!

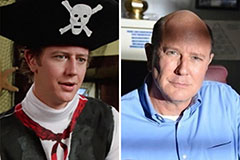

Tony Danza Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now!